Portable CMM (PCMM) 3D Laser Scanning

The non-contact nature and outstanding flexibility of 3D Laser Scanning, trusted for its precision, reliability, velocity and ease of use make it perfect for measuring a wide array of components in a diverse range of environments.

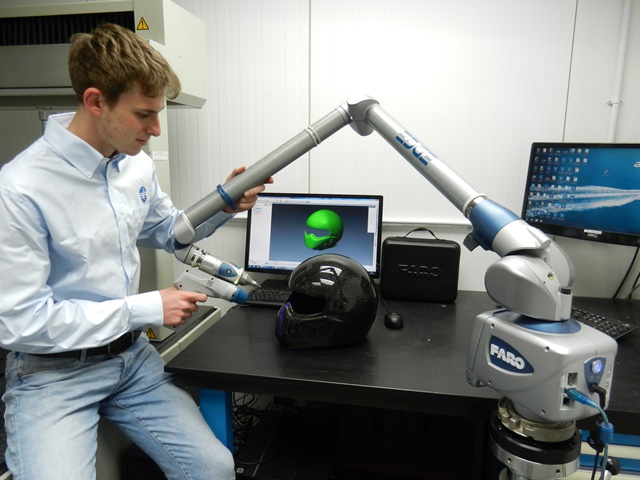

Tri-State Metrology’s portable CMM equipment includes one of the most popular and versatile portable 3D Scanning technologies on the market, the Faro HD Laser Scanner. The Faro laser scanner projects a laser across a part surface and calculates the distance from the sensor to the object surface, using trigonometric methods to generate point cloud data. The distinctive attraction of the Faro is that it provides portable, state-of-the-art, scanning and measurement technology directly to you. Our portable 3D laser scanning service provides on-site support for reliable and accurate scanning of parts, fixtures, and machinery at your facility.

Our Faro equipment is integrated with PolyWorks, a provider of universal 3D metrology software solutions, which allows us to be flexible in our project-based application choices. PolyWorks makes everything from dimensional inspection to point cloud analysis and reverse engineering possible. Learn more about our CMM programming capabilities extending beyond PolyWorks.

Popular 3D Laser Scanner Applications:

- Fast and precise 3D digitalization

- Simple part-to-CAD inspection

- Inspection of complex geometric features

- Reverse engineering

- Gap-and-flush inspection

- Tactile measurement of soft and delicate components

- Fixture certification

3D laser scanning is a contactless method for collecting large quantities of point data from an item by using the light from the laser. The collected points have multiple applications from color mapping of the scanned object’s deviation from a CAD model to using the point cloud to create a CAD model that did not previously exist. As part of the reverse engineering process, software such as PolyWorks can convert the scan data into a polygonal model (.stl).

Scanned items can be as tiny as a human hair or larger than a full-size SUV, conditioned on a 3D laser scanner setup. Our 3d scanning services have been used across a broad range of industries for dimensional inspection analysis and reverse engineering projects.

Contact Us

Tri-State Metrology’s state of the art facility houses a growing network of some of the brightest minds in the industry. Our engineers are capable of more than just contract inspection services. With our broad knowledge in machining, forging, thermoforming, injection molding, and blow molding we are capable of providing both on and off-site quality inspections. Complete with 17025 and ISO 9001 certifications, we are here to assist with your metrology needs.